|

|

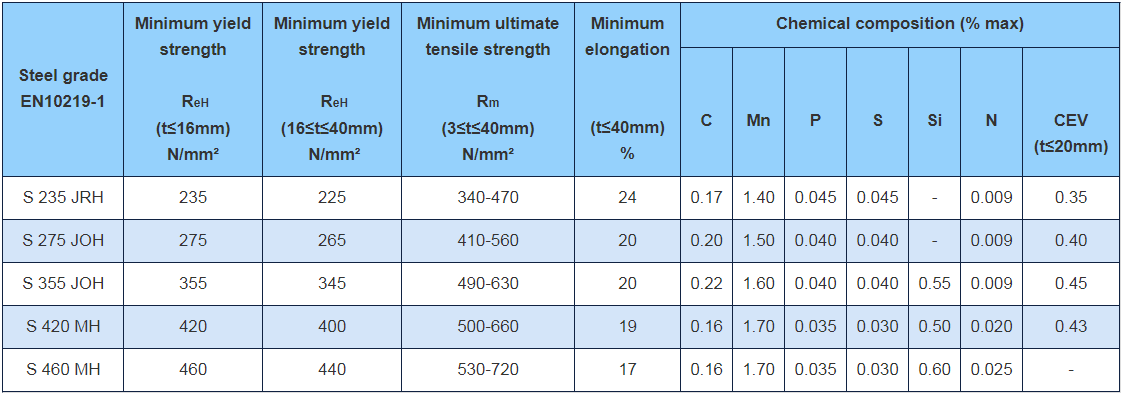

Minimum yield |

Minimum yield |

Minimum ultimate |

Minimum |

Chemical composition (% max) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|||||

S 235 JRH |

235 |

225 |

340-470 |

24 |

0.17 |

1.40 |

0.045 |

0.045 |

- |

0.009 |

0.35 |

S 275 JOH |

275 |

265 |

410-560 |

20 |

0.20 |

1.50 |

0.040 |

0.040 |

- |

0.009 |

0.40 |

S 355 JOH |

355 |

345 |

490-630 |

20 |

0.22 |

1.60 |

0.040 |

0.040 |

0.55 |

0.009 |

0.45 |

S 420 MH |

420 |

400 |

500-660 |

19 |

0.16 |

1.70 |

0.035 |

0.030 |

0.50 |

0.020 |

0.43 |

S 460 MH |

460 |

440 |

530-720 |

17 |

0.16 |

1.70 |

0.035 |

0.030 |

0.60 |

0.025 |

- |

|

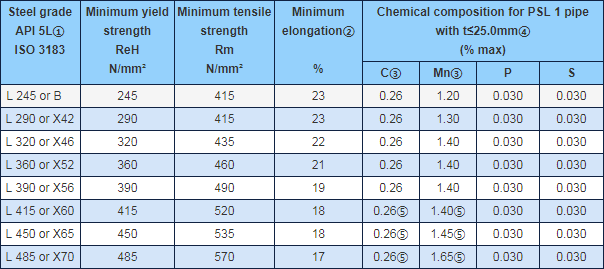

Steel grade |

Minimum yield strength |

Minimum tensile strength |

Minimum elongation② |

Chemical composition for PSL 1 pipe with t≤25.0mm④ |

|||

|---|---|---|---|---|---|---|---|

C③ |

Mn③ |

P |

S |

||||

L 245 or B |

245 |

415 |

23 |

0.26 |

1.20 |

0.030 |

0.030 |

L 290 or X42 |

290 |

415 |

23 |

0.26 |

1.30 |

0.030 |

0.030 |

L 320 or X46 |

320 |

435 |

22 |

0.26 |

1.40 |

0.030 |

0.030 |

L 360 or X52 |

360 |

460 |

21 |

0.26 |

1.40 |

0.030 |

0.030 |

L 390 or X56 |

390 |

490 |

19 |

0.26 |

1.40 |

0.030 |

0.030 |

L 415 or X60 |

415 |

520 |

18 |

0.26⑤ |

1.40⑤ |

0.030 |

0.030 |

L 450 or X65 |

450 |

535 |

18 |

0.26⑤ |

1.45⑤ |

0.030 |

0.030 |

L 485 or X70 |

485 |

570 |

17 |

0.26⑤ |

1.65⑤ |

0.030 |

0.030 |

① API 5L (2007):American Petroleum Institute / ISO 3183 (2007). PSL: Product Specification Level.

② Minimum elongation:depends on tensile test piece cross-sectional area.

③ For each reduction of 0.01% below the specified max C concentration, an increase of 0.05% above the specified max Mn concentration is permissible, up to a max of 1.65% for grades L245/B to L360/X52, 1.75% for L390/x56 to L450/x65 and 2.00% for L485/x70.

④ 0.5% max for Cu,0.50% max for Ni, 0.50% max for Cr, 0.15% max for Mb.

⑤ Unless otherwise agreed.